英语原文共 214 页,剩余内容已隐藏,支付完成后下载完整资料

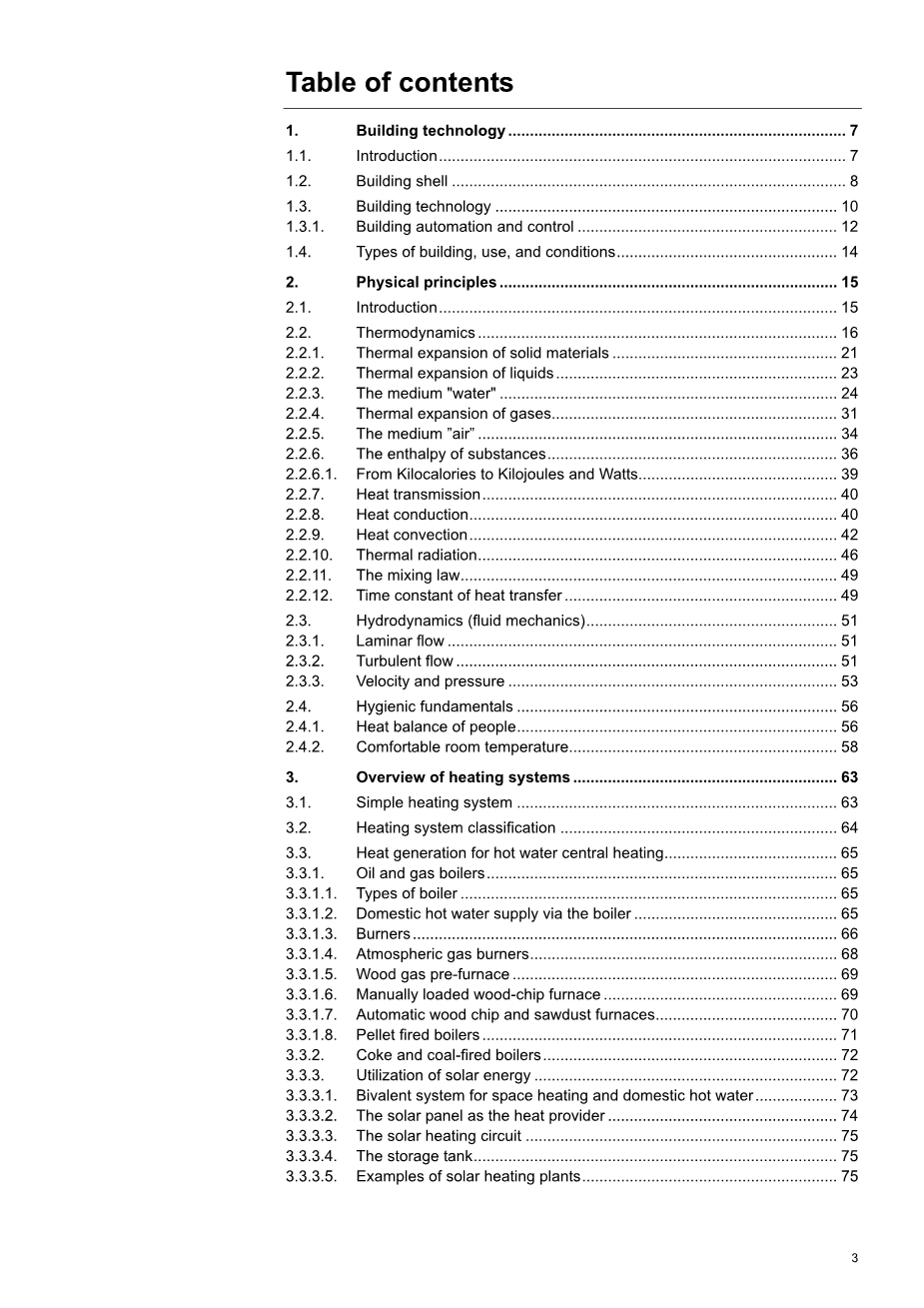

Function

Mechanical design based on working media

-

-

- Heating coils

-

Used to heat the supply air to the required temperature (e.g. the discharge air tem- perature of a room heating system).

- Finned-pipe heat exchanger, operated with low temperature hot water, high tem- perature hot water or refrigerant vapor (Fig. 6-19)

- Electric heating coils (Fig. 6-21)

Heating coils are used as pre-heaters or re-heaters in air heating and air condition- ing plants.

Fig. 6-19 Finned-pipe heating coil and example of installation in a plant (with a mixing circuit)

Heat exchangers normally show a non-linear response in terms of the mass flow passing through them and the associated output. Depending on how they are con- structed and on the supply temperatures, this 'heat transfer characteristic' varies from a steep curve to a shallow curve, as expressed by the 'a-value'. The charac- teristic curve of the heat exchanger is shown in relation to the maximum volume

flow rate Vamp; 100 and the maximum output Qamp; 100 .

Fig. 6-20 Heat-exchanger characteristic curves and the associated a-values

Electric heating coils have a number of built-in spiral heating elements which be- come hot as the current flows through them. They emit the heat acquired in this way into the air. They are installed in areas where there is no hot water heating, or where the connection point is too far away, or where, for other reasons, an LTHW heating coil cannot be used. Owing to the risk of fire, electric heating coils require special safety arrangements and devices (e.g. safety thermostat, fan run-on etc.)

Fig. 6-21 Electric heating coil (steel pipes with integrated heating coils; Source: Loysch)

6.2.6 Chilled water cooling coil

Chilled water cooling coils are finned-pipe heat exchangers operated with flow/return water temperatures of e.g. 6/12 °C or 8/14 °C. Cooling coils normally require a larger heat-transfer surface area than heating coils, because on average, the difference in temperature between the surface of the cooling coil and the air is smaller. The requirement for a greater surface area is fulfilled in design terms by several rows of pipes arranged one behind the other. If the air is to be de- humidified as well as cooled, then the cooling coil must be connected hydraulically as shown below, i.e. in a diverting circuit. If the air only has to be cooled, then a mixing circuit is acceptable.

2

1

Fig. 6-22 Example of installation of a chilled water cooling coil in the plant (with diverting circuit)

- Chilled water inlet

- Air inlet

6.2.7 Direct expansion cooling coil

A finned-pipe heat exchanger which acts as the evaporator in a refrigerant cycle is installed directly in the air flow as a cooling coil. As a rule, this solution is reserved for compact cooling units which also have a built-in compressor and condenser.

Fig. 6-23 Direct expansion cooling coils Various types (left)

Detail showing connection of the refrigerant distributor (right)

6.2.8Humidifiers

Principles

Air washers

Water atomizers

- Humidification through the evaporation of water

-

Humidification through the introduction of steam

-

-

- Evaporative humidifiers

-

-

Evaporative humidifiers include air washers, water atomizers and surface water evaporators.

Water is pumped from a reservoir into the spray nozzles distributed in the air flow. The majority of the fine droplets evaporate and become steam, in the process of which the latent heat of vaporization is extracted from the air flow. Since the energy required for evaporation is taken solely from the air, the air cools down (adiabatic cooling). The non-evaporated water droplets are separated in a drip screen at the air washer outlet, and then routed back to the collecting tray.

|

2 |

||||

|

1 |

||||

|

2 |

||||

|

3 |

||||

|

3 |

||||

|

4 |

Fig. 6-24 Principle of the air washer, and example of construction (Source: Baehr)

Fig. 7-15

- Spray nozzles (several adjacent rows, often with the spray directed against the air flow)

- Drip screen

- Collecting tray

- Circulating pump

The water is converted by use of atomizing nozzles into a fine spray mist. The wa- ter droplets or 'aerosols' are so small that they are initially suspended in the air, and then evaporate completely. The latent heat of vaporization is removed from the air, which becomes slightly cooler (adiabatic cooling).

Fig. 6-25 Surface water evaporator (built into ventilation unit)

Surface water evaporator

Cold water steam humidifier

Porous ceramic plates with a large surface area are located downstream of the wa- ter atomizer described above. Any aerosols which have not yet evaporated are trapped by these plates and then evaporate fully (see Fig. 6-25).

In plants required to satisfy stringent hygiene requirements, cold water steam gen- erators can be used for humidification. Compared with the methods of humidifica- tion described above, the characteristic features of a cold water steam generator are a much lower consumption of water and energy.

The incoming air is f

剩余内容已隐藏,支付完成后下载完整资料

资料编号:[150892],资料为PDF文档或Word文档,PDF文档可免费转换为Word

课题毕业论文、开题报告、任务书、外文翻译、程序设计、图纸设计等资料可联系客服协助查找。

您可能感兴趣的文章

- 饮用水微生物群:一个全面的时空研究,以监测巴黎供水系统的水质外文翻译资料

- 步进电机控制和摩擦模型对复杂机械系统精确定位的影响外文翻译资料

- 具有温湿度控制的开式阴极PEM燃料电池性能的提升外文翻译资料

- 警报定时系统对驾驶员行为的影响:调查驾驶员信任的差异以及根据警报定时对警报的响应外文翻译资料

- 门禁系统的零知识认证解决方案外文翻译资料

- 车辆废气及室外环境中悬浮微粒中有机磷的含量—-个案研究外文翻译资料

- ZigBee协议对城市风力涡轮机的无线监控: 支持应用软件和传感器模块外文翻译资料

- ZigBee系统在医疗保健中提供位置信息和传感器数据传输的方案外文翻译资料

- 基于PLC的模糊控制器在污水处理系统中的应用外文翻译资料

- 光伏并联最大功率点跟踪系统独立应用程序外文翻译资料